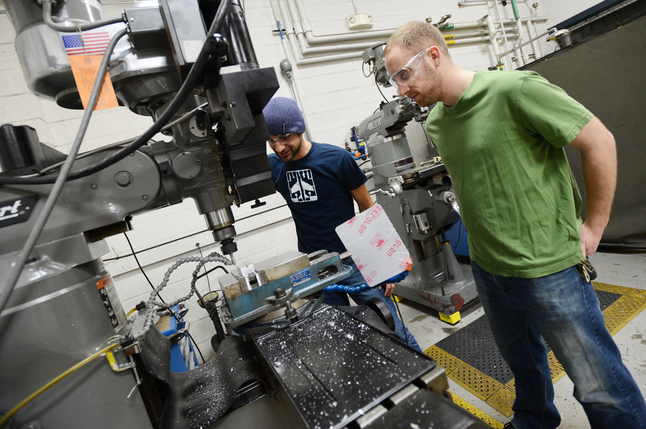

SkySpecs chief engineer Pat Senatore operates a CNC mill as CEO Danny Ellis looks on as they work cut out a mold for a prototype in the Wilson Student Team Project Center at the University of Michigan on Friday, Feb. 22, 2013.

Melanie Maxwell I AnnArbor.com

This past August, the U-M team met that objective when its design outperformed robots from 20 other universities from around the world.

It was the third year participants attempted to conquer the competition's sixth mission wherein competing robots had to fly into a building through an open window, navigate the course to retrieve a target flash drive, leave a decoy in place of the drive, and exit the building.

No robot fulfilled the mission objectives completely. In fact, some self-terminated inside the course, per the competition's rules.

On their best run, the U-M team didn't bother programming its robot to pick up the flash drive, due to retrieval malfunctions it had suffered on previous runs.

"In the last attempt, we just wanted to prove that we could be at first place," Ellis said.

That prudence paid off -- their robot stole the show when it autonomously navigated the entire course in under five minutes without bumping into anything.

Inspired by their success, Ellis and his peers aimed their sights higher. They started a company to commercialize autonomous aerial robot technology for industrial applications.

The company, SkySpecs, took the $50,000 first place prize at the fifth annual Michigan Clean Energy Venture Challenge Feb. 15 at the Ross School of Business.

"It’s really not about the prize money, it’s just a small incentive," Ellis said.

SkySpecs was one of 20 teams from 10 Michigan universities that made it to the challenge's semi-finals.

A prototype system the Michigan Autonomous Aerial Vehicles developed.

Melanie Maxwell | AnnArbor.com

Although only recently founded, the company has raised $100,000 from private investors and business competitions like the clean energy challenge.

Ellis said production hasn't started yet and will be small-scale for the first few years.

"We have to prove there is a market segment, paying customers, and a solution that fits their problems," he said. "...Our target is to be selling 600 units a year by 2017."

The robot the company is developing will be significantly different from the one the U-M team designed.

"The student team's vehicle was built for a very particular application," he said. "We are designing for commercial and industrial applications."

Ellis estimated the production model will weigh around 11 pounds and cost about $50,000, due largely to its various expensive sensors.

"The vehicle is incorporated with cameras, ultrasonic sensors, thermal sensors," he said.

While the U-M team's robot used a laser sensor to scan 40,000 points per second as it navigated an environment, SkySpecs' production model will rely on sophisticated cameras instead.

"We’re really focusing on the visual side, basically using the cameras the way a human does," Ellis said.

The robot's modular design features a circular center platform from which four rotor-bearing arms extend. A number of specialized cameras or sensors can be installed interchangeably on top of the platform.

"Our biggest goal is anyone can take it out of the box and fly it, just completely untrained," he said.

The robot will not require any programming by users. Instead, they will interact with it via a touch-screen tablet.

"This will have high level commands and the ability to place way-points in the environment that the vehicle will follow," he said.

The high-level commands will vary with market and application, but may include take off, land, return to home, hold position, explore environment and more.

"The learning curve to operate our vehicle will be minimal," he said.

Ellis said "no tools are necessary." In fact, he said an engineer or soldier could remove the arms or exchange the sensors without even taking her or his gloves off.

"It can go in a harsh environment, be waterproof, run into things and bounce off and be fine," he said.

Though a production model hasn't been built yet, Ellis said the molds are ready and the airframe will be done this week.

SkySpecs plans to market its robots to civil engineers first. Ellis said there are currently many situations where engineers expend large amounts of time in hazardous environments inspecting structures and equipment.

"It’s expensive, time consuming and dangerous," he said. "We want to remove that need."

The robot, though unable to fix anything, would autonomously fly to whatever destination an engineer sent it to and use its sensors to gather large amounts of data that the engineer could analyze later.

Ellis said this would enable engineers to analyze the integrity of bridges, large wind turbines and other structures without putting themselves in danger.

"We thought early on that there might be some resistance in the market, because we’re removing people’s jobs," Ellis said. "But they don’t want to be hanging from those structures either We’re not necessarily removing a job. We’re just giving them a different tool to complete their job."

But Ellis said civil engineering is only the beginning.

"There are so many applications with the same exact platform," he said.

For example, Ellis said snowboarders could use them to take aerial photos and video for personal or promotional use.

A more conventional application the group is considering is military reconnaissance. Ellis said SkySpecs would have a strong competitive edge in that market because their design doesn't require user control, making it very attractive to soldiers.

"If they have to take the gun out of their hands to use a controller, then they don’t want to do it," he said. "So they want it to be autonomous--just click a button to deploy and let it do its thing while they can continue on their mission. "

SkySpecs currently has four founders and two employees. Ellis said for the time being, the company's base of operation is his house.

Though the SkySpecs crew will no longer participate on the U-M student team, Ellis said the team is still running and the company may offer employment to future students.

"As we grow and as we can employ more, it’s a great feeding ground for us to go to," he said.

Kody Klein can be reached at kklein@mlive.com.